Oil and gas are molecules composed of hydrogen and carbon atoms and are thus called “hydrocarbons.” Hydrocarbons are flammable/combustible and can be used to make a variety of fuels, but they are also highly versatile for other uses such as the manufacture of plastics and a wide variety of other petrochemical products. Hydrocarbons gain their exceptional versatility primarily from their carbon atoms. Carbon atoms bond exceptionally well with other atoms, are easy to modify into other chemical and structural variations, and can form more compounds than any other element. Carbon is also a critical component of all lifeforms and the carbon and hydrogen remains of organisms that lived in the ancient past are the source of oil and gas.

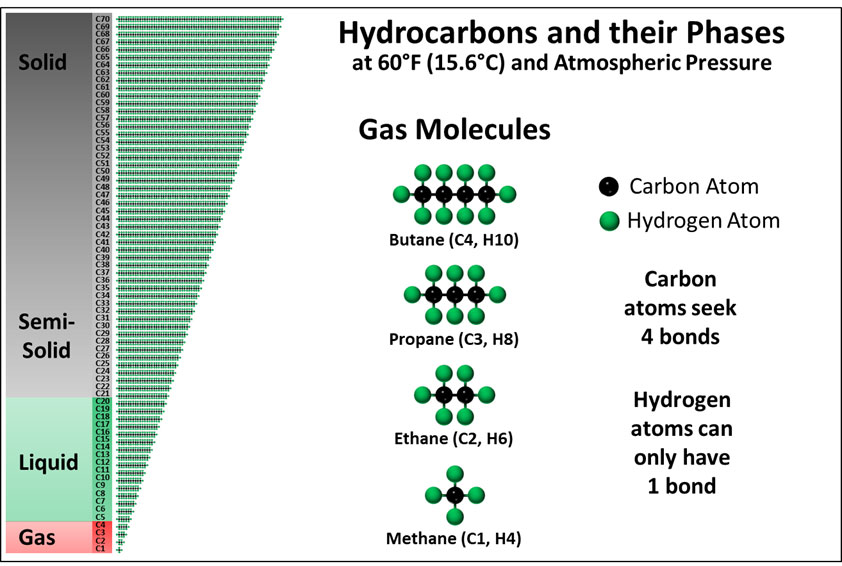

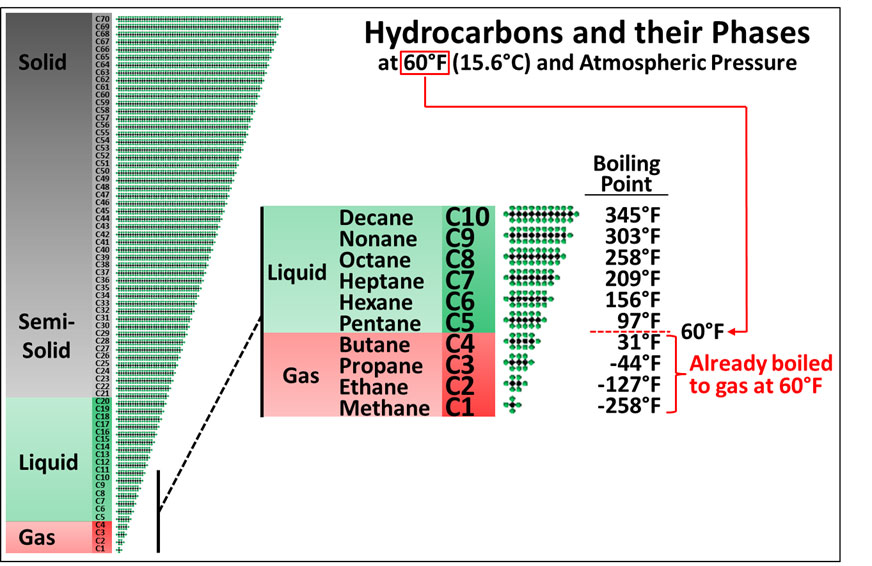

Hydrocarbons can range in size from one carbon atom per molecule to 70 or more. At normal conditions (which we'll define as 60°F/15.6°C and atmospheric pressure), the smallest and lightest hydrocarbons, with 4 or fewer carbon atoms, behave as gases. These gases are called methane (C1), ethane (C2), propane (C3) and butane (C4). From C5 to about C20, molecules behave as liquids, with increasing viscosity. Beginning at about C21, molecules do not flow easily and begin to take on semi-solid characteristics, increasing eventually to solid. You can see that oil and gas are not radically different substances – they are just different sizes and weights of a similar substance.

We are all aware that water can be a solid (ice), melt into a liquid, and boil into gas (vapor) depending on temperature (and pressure). Hydrocarbon molecules also have gas, liquid and solid phases, with lighter molecules requiring less heat to melt and boil than larger molecules. Methane, ethane, propane and butane behave as gases at 60°F because it is above their boiling points. If the temperature is lowered enough, they will liquefy and eventually solidify. Conversely, if the temperature is raised, liquid molecules will begin boiling into gases and solids will begin melting into liquids. The fact that hydrocarbons can be forced into phase changes, and at differing temperatures, is important to the way that refineries and gas plants sort molecules, or ranges of molecules, into different types of products. Also, the ability to liquefy gases makes them easier to transport and store, and some types of gases, such as propane and butane, are typically marketed as liquids.

GASES

Gas can be produced with or without oil present in the same reservoir. When produced gas comes out of the ground, it is usually at least 70% methane but can also contain heavier gases, usually in declining percentages as molecule size increases (less propane than ethane and less butane than propane). Produced gas can also be carrying suspended light hydrocarbon liquids, similar to how humid air contains suspended water molecules. As produced gas cools and expands at the surface, a portion of any suspended liquids may begin to condense out of the gas as it passes through field processing equipment. This liquid is called "condensate," is similar to gasoline, and can be used by either refineries or petrochemical producers. Produced gas that contains a significant amount of heavier gases and suspended liquids is called "wet" gas or "rich" gas, and gas that is almost pure methane is called "dry" gas or "lean" gas. Heavier gases and suspended liquids generally have a higher value than methane, so gas producers tend to favor drilling in areas where the gas is wet/rich. Produced gas can also contain contaminants such as water molecules, CO₂, and hydrogen sulfide (H₂S).

Gas that is wet/rich or contaminated must be processed before it can enter a long-haul pipeline because those pipelines are designed to carry almost pure methane. Gas gathering lines will route wet/rich gas to a gas processing plant and it will separate out heavier gases, any remaining suspended liquids, and contaminants. Most gas plants separate the heavier gases from methane using a cryogenic process to lower the temperature and pressure of the gas to a point where everything but the methane liquefies and drops out. The remaining methane stream flows into a gas pipeline and the liquefied gases, called natural gas liquids or “NGLs,” will be sent to a fractionation facility to be separated and marketed as purity products. Ethane has a lower value than propane and butane and prices sometimes dip to the point that processers leave it in the methane stream to be sold as a gas rather than a liquid. This is called “ethane rejection.”

The almost-pure methane in pipelines is delivered to residences, businesses, industrial plants and electrical utilities to be used as fuel. Compressed methane (referred to as compressed natural gas or “CNG”) can also be used as a motor fuel in specially-equipped vehicles, but is not currently in widespread use for that purpose. Methane can also be used to produce ammonia for use in fertilizers, as well as methanol and other products.

Methane is sometimes liquefied to reduce its volume (to about 1/610th) so that it can be transported by ocean-going carriers to distant markets that can’t be accessed by pipeline. This is called liquefied natural gas, or “LNG,” and it is re-gasified at its destination point. The extreme degree to which methane must be chilled for liquefaction is an expensive process that can only be justified in certain, large-scale situations and projects may have significant exposure to market price fluctuations. The U.S. has several LNG liquefaction facilities with more under construction.

Ethane, propane and butane are valued as feedstocks by the petrochemicals industry. Their small-sized carbon chains make good building blocks for petrochemical products such plastics, polyester, synthetic rubber, coolant/antifreeze, solvents, detergents, etc., etc. Different gases are favored for different petrochemical applications.

Propane and butane are commonly sold in liquid form to be gasified for fuel, particularly in rural areas that do not have access to a gas pipeline, and also for outdoor grills. Liquefied gas has an advantage because it's reduced volume allows storage of more energy in a given amount of tank space. Propane is particularly favored because it is safe and practical to store as a liquid in tanks across a wide range of normal temperatures. Liquid methane or ethane would have too much tank pressure in warm climates because it is so far above their boiling points that they are difficult to contain. On the other hand, an outdoor tank filled with liquid butane would be unsuitable in areas where winter temperatures fall below its 31°F boiling point because it would drop to zero pressure and no longer be capable of providing a gas flow. Butane is a better fuel, however, for something like a lighter that people carry around in their pockets because butane has the lowest liquid pressure and can be safely stored in a lighter's cheap plastic container.

CRUDE OIL

Crude oils can contain a wide-ranging mix of liquid and solid hydrocarbon molecules, as well as some dissolved gases. The average density (“gravity”) of crude oil can range from thin (“light”) to highly viscous (“heavy”) depending on the average composition.

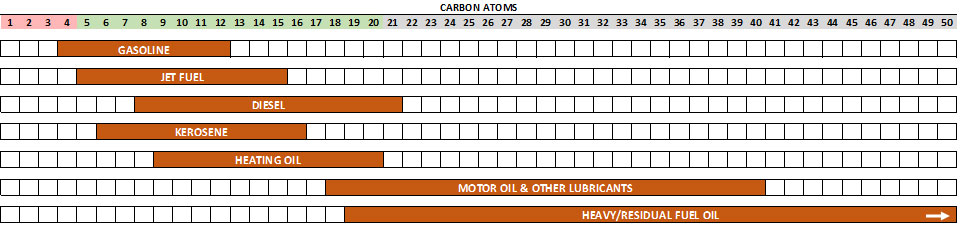

The first stage in the refining process is to heat crude oil and run it through a distillation tower that separates molecules into size ranges based on their boiling points. These ranges are further processed into finished refined products. The major categories of refined products and their approximate molecular composition is shown below.

Heavy/residual fuel oil is the basically the leftovers of the refining process and is a dense, dark, viscous liquid burned in industrial furnaces or used as fuel for large ships (called “bunker” fuel).

Transportation fuels such as gasoline, jet fuel and diesel are the most valuable products so refineries use heat and catalysts in a process called "cracking" to break some of the lighter fuel oil molecules into smaller molecules that can be used for transportation fuels. The most-sophisticated refineries use a process called "coking" that can break even the heaviest fuel oil molecules into smaller molecules.

Crude oil composition is a lot more complicated than we will address in this post. For example, the diagrams we used here show molecules as long straight chains but hydrocarbons occur naturally in variety of structures including branched chains, rings, connected rings, or a mixture of those, and the hydrogen-to-carbon ratio can also differ. This is significant because variations of same-sized molecules can have quite different performance characteristics, ranging from poor to excellent, and refiners can't separate them all. Thus, when we indicate that gasoline is made of molecules ranging from C4-C12, it is actually a blend of a large variety of C4-C12 molecular variations ranging from poor to excellent, and the average quality must be good enough to meet octane standards. There are also environmental regulations limiting the use of some variants because they are more polluting or otherwise harmful to the environment.